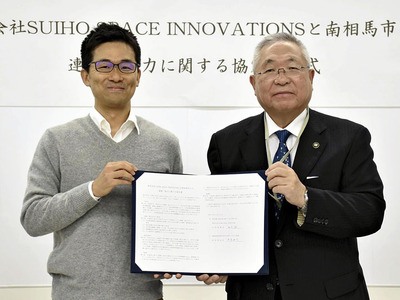

MINAMI-SOMA, Fukushima — Zip Infrastructure, Inc., a startup in Minami-Soma, Fukushima Prefecture, is pioneering the future of urban transportation by developing a revolutionary self-propelled ropeway system.

Due to low installation costs and traffic-free operation, municipalities nationwide are showing keen interest in the transportation system.

“Our goal is to boost the local economy in cooperation with local businesses, and to attract people and industries to the Hamadori area [Fukushima Prefecture’s coastal area] with technology developed in Minami-Soma,” said an official of Zip Infrastructure who oversees the development.

福島県南相馬市で新たな交通手段を生み出すプロジェクトが進んでいる。市内に本社を置くベンチャー企業「ジップインフラストラクチャー」が中心となり、自走式ロープウエーが開発されている。低コストで設置でき、交通渋滞も関係ないことから、全国の複数自治体が関心を寄せる。開発担当者は「地元企業と一緒に地域を盛り上げ、浜通りに人も企業も集まってほしい」と話し、南相馬から新技術を生み出すため力を込める。

Last year, the company moved its headquarters to Minami-Soma from Kanagawa Prefecture, drawn by the Fukushima Robot Test Field and other environments. The firm is currently constructing a 450-meter-long test line at the field for future practical use. Part of the line is expected to be completed around June or July, and the entire line is expected to be completed by fiscal 2026.

Michihito Shimauchi, 31, manager of the Fukushima Test-Line Project Section at Zip Infrastructure, expressed his passion for developing the transportation system, which the company calls “Zippar.”

“We want to create something that not only provides transportation but also adds value to the city and attracts more people,” he said.

The company plans to deploy the system in urban parks and factories in fiscal 2028. The goal is to introduce it as a form of urban transportation from fiscal 2030 and beyond.

同社は昨年、福島ロボットテストフィールドなどの環境に魅力を感じ、神奈川県から本社を移した。現在は実用化に向け、同フィールドに全長約450メートルの試験線を建設している。今年6~7月に一部が完成し、26年度中に工事完了する予定だ。

「単なる移動だけでなく、街の価値を上げ、より人が集まるものにしたい」。福島試験線PJ推進課長の島内道人さん(31)は、同社が「ジッパー」と呼ぶこの交通システムの開発に懸ける思いを語る。計画では、28年度に都市公園や工場内での実用化を目指すほか、30年度以降に都市交通としての導入が目標だ。

Zippar fares are expected to be similar to those of trains and buses, with a range of 1-10 kilometers. The vehicle, designed for about 12 passengers, will reach speeds in excess of 30 kilometers per hour. It will be self driving, powered by a battery-based electric system derived from electric vehicles.

運賃は鉄道やバスと同程度を見通す。運行距離は1~10キロを想定。定員は12人程度で、最高時速は三十数キロ。運転手のいらない自動制御で、動力は電気自動車をベースとしたバッテリーによる電動。

Unlike conventional ropeways, which use a single moving rope, Zippar uses two ropes, allowing the vehicle to move independently. By running on rails for curves and other sections, it allows for flexible route designs that were difficult with traditional ropeways.

“That’s the key technological point,” Shimauchi said. While ropeways are generally vulnerable to wind, this system, using two ropes, aims to operate in wind velocity of up to 30 meters per second.

The estimated construction cost is between about ¥1 billion to ¥2 billion per kilometer, which is about 20% of the cost of developing a monorail and 10% of developing a subway.

ロープウエーは通常、1本のロープを車両がつかみ、ロープ自体が動くのに対し、自走式ロープウエーは2本のロープ上を車両自らが動く。カーブなどはレールを走ることで、これまでのロープウエーには難しかった柔軟な路線設計も可能にした。島内さんは「そこが技術のポイント」と胸を張る。ロープウエーは一般的に風に弱いが2本のロープを使うことで、運行風速は風速30メートル以下を目指す。

1キロ当たりの建設コストは約10億~20億円と見込んでおり、モノレールの5分の1、地下鉄の10分の1程度となるという。

Despite being in the early stage of development, the system’s many appealing qualities have attracted interest from various municipalities. Tomiya, Miyagi Prefecture; Ishikari, Hokkaido; and Tomigusuku, Okinawa Prefecture are considering adopting the system, according to the company. The cities of Fukuoka and Niigata, as well as a Philippines-based development corporation, have also expressed interest.

The company plans to conduct multiple test runs, placing emphasis on landscape impact and safety.

“We aim to create a system that can transport passengers to a safe location using its own battery during power outages. Safety is our top priority, and we will continue to advance our technological development,” Shimauchi said.

開発中だが、多くのメリットがあることから注目する自治体などは多い。同社によると、宮城県富谷市や北海道石狩市、沖縄県豊見城市が導入の可能性を検討しており、福岡市や新潟市のほか、フィリピンの開発公社も関心を持つ。

今後は景観への影響や安全性を重視し、試験走行などを重ねる方針。島内さんは「停電時も自前のバッテリーで安全な場所に乗客を運ぶシステムを目指す。安全最優先は確実に守り、技術開発を進めていきたい」と話す。

The company has received cooperation from local businesses for the construction of the test line and the procurement of research and development components. They also envision establishing a mass-production factory for the vehicles in the future.

“To express our gratitude for the support extended to us, we are committed to settling down and fostering growth in Minami-Soma,” he said.

( Translated by The Japan News )

試験線の建設や、研究開発用の部品調達では地元企業の協力を受けている。将来的には車両を量産できる工場の整備も見据える。島内さんは「南相馬に腰を下ろして成長し、これまでの支援の恩返しをしたい」と意気込む。

【 2025年3月19日付・福島民友新聞掲載 】